PTFE bushes are important for machines and moving parts. They help ensure smooth operation. Choosing the right PTFE bushing is key to manufacturing. It helps when components need low friction and heat resistance. But not every product that bears the term PTFE guarantees performance. If you spot quality PTFE bushings, you can avoid constant replacements. This will save you time and money.

In this blog, we will explain five simple ways of checking PTFE bushing quality. This guide helps you identify quality PTFE bushings. You can do a few simple tests before buying or installing them.

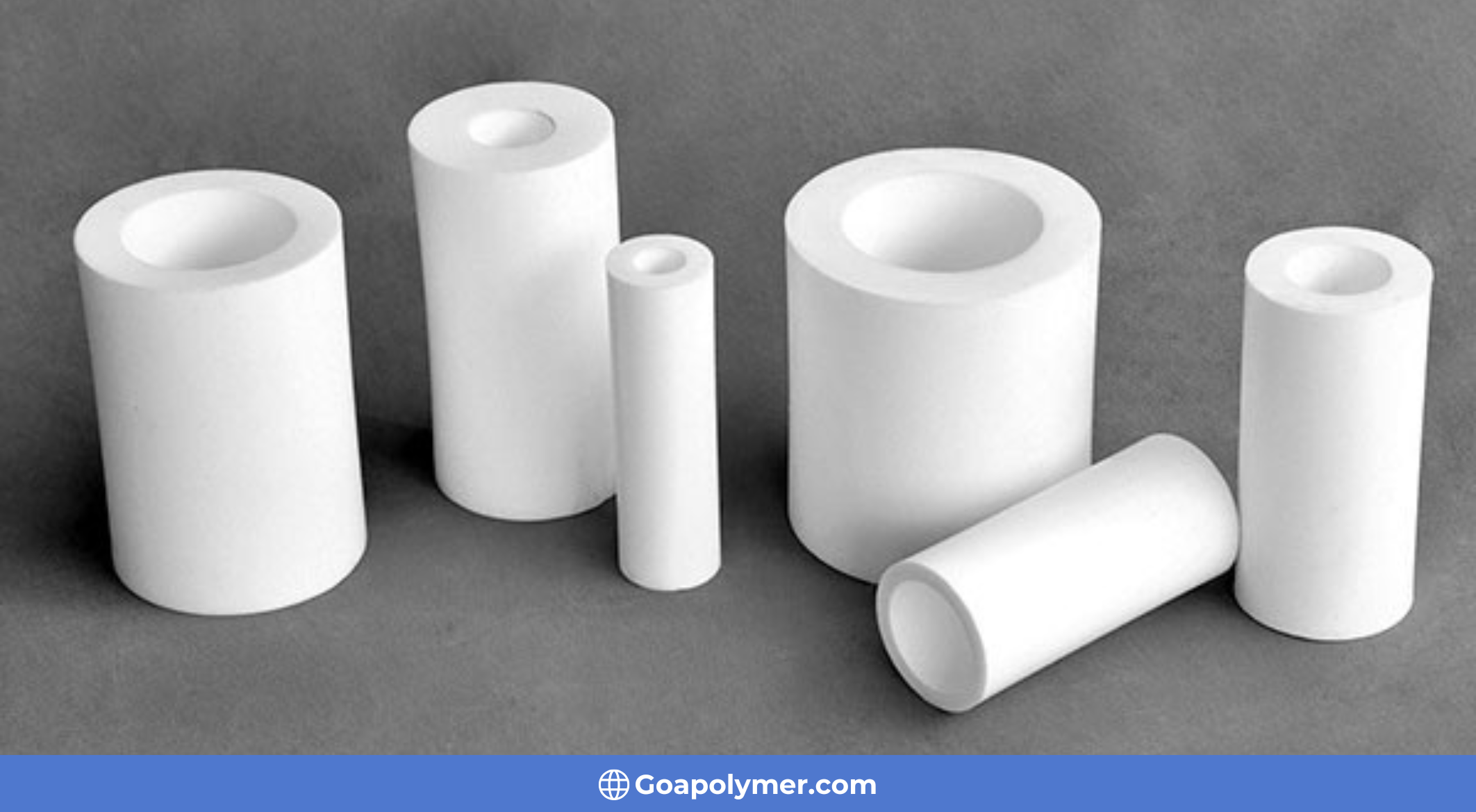

5 Ways to Identify Quality PTFE Bushings

Selecting the right PTFE bushings is crucial for optimal machine performance and extended lifespan. Here are some important points that will help you identify the quality of PTFE bushings:

1. Check the Purity and Grade of PTFE Material

Material quality stands as the primary element that requires assessment. PTFE exists in multiple grades under the name Polytetrafluoroethylene. High-quality bushings get their material from virgin PTFE. This material is 100% pure and offers better performance. The purity of PTFE influences the bushing’s performance.

Any roughness, uneven texture, or visible particles on the surface indicates poor manufacturing. Proper finishing is required in precision machinery or sensitive environments. Pure PTFE is good for smoothness, durability, and consistent results.

Here’s what you should look for:

- Virgin PTFE: This pure PTFE contains no additives or fillers. The material resists chemicals and reduces friction. It also continues to perform well over time.

- Filled PTFE: The process adds bronze, carbon, and glass. This boosts strength and wear resistance. This works well if the application needs extra support. However, you must spread the filler in an even layer.

- Recycled PTFE: This is costlier but less reliable. It can have impurities and, when pressured, may crack or deform.

2. Inspect the Surface Finish and Dimensions

A smooth and accurate finish is another mark of a cheap PTFE bushing. Little defects can affect the performance level and might even damage others. A poor fit of the bushing can cause vibration, more wear, or even machine failure. Correct dimensions assure stability, reducing maintenance costs.

Important checks include:

- Surface Smoothness: A polished surface serves as the main feature of superior bushings. The system operates with reduced friction, allowing parts to move without obstruction.

- Dimensional Accuracy: Verify if the inside and outside diameters meet the specified tolerances. Precision machines manufacture good bushings.

- Roundness and Shape: If the shape is uneven or misshapen, the product was not made correctly.

3. Test the Load and Temperature Resistance

A PTFE bushing finds its use in adverse working conditions. It must handle heavy loads, constant movement, and sometimes extreme temperatures. High resistance against temperatures and chemicals ensures a long operational life.

When selecting a PTFE bushing, check its heat resistance, which is up to 260°C. Its non-reactive nature with oil, acid, and solvents is also key. This is important in the case of Teflon suspension bushings for automobiles.

Factors to consider:

- Load Capacity: Good PTFE bushings support heavy loads without deformation. Virgin PTFE can handle moderate loads. In contrast, filled PTFE bushings manage much heavier forces.

- Temperature Range: PTFE performs well between -200°C and +260°C. Ensure your product matches your working conditions.

- Wear Resistance: The best high-quality PTFE bushings don’t wear down during use and work well in high temperatures due to their wear resistance property.

4. Check for Certifications and Quality Standards

PTFE bushing production requires reputable manufacturers to follow international quality standards. The certification body certifies the product. Tests confirm its performance, safety, and consistency.

Inspectors and testers examine certified products to ensure they are defect-free. This system protects users from defective or substandard bushings.

Key standards to look for:

- ISO Certification: This means the manufacturer implements a quality management system that is accepted worldwide.

- ASTM Standards: These are guidelines from the American Society for Testing and Materials. They cover materials and performance and are commonly used for PTFE-based products.

- RoHS Compliance: This means the product is free from hazardous substances. It’s crucial for safety and the environment.

5. Evaluate the Manufacturer’s Reputation and Certifications

The source of the product is most important when it comes to its quality. Manufacturers with a good reputation among customers make reliable PTFE bushings. Other than the product itself, there is technical support and after-sales service.

A great material can fail if it is not matched correctly with the application. The expert manufacturer will help you avoid mistakes by offering the right solution.

Points to consider:

- Experience in the Industry: Long-standing organizations create better manufacturing methods and enhance quality control systems.

- Customer Feedback: Look for user reviews and feedback. Good feedback is usually a sign of a good vendor.

- Technical Support: Good manufacturers help choose a bushing for your application and offer installation, maintenance, and material selection advice.

- After-Sale Service: Services after sale assure easy replacement or help with any hitch.

Conclusion

Selecting quality PTFE bushings is essential for smooth machine operation and long-term durability. Inferior bushings accelerate wear, cause breakdowns, and increase maintenance costs. To ensure lasting performance, check the material grade, surface finish, load and temperature resistance, certifications, and manufacturer’s reputation. This guarantees that production standards are reliable.

At Goapolymer, quality is our priority. We manufacture PTFE bushings under strict quality controls to meet industry standards. High-quality bushings are a smart investment for any industrial application, boosting machinery efficiency, reducing downtime, and saving costs over time.

Frequently Asked Questions

Virgin PTFE is pure and therefore works well for most applications. Filled PTFE has fillers such as bronze, carbon, or glass to impart strength and wear resistance for heavy-duty purposes.

With good usage, quality PTFE bushings can last for years. However, their life depends on load, temperature, speed, and usual maintenance.

Yes, PTFE is endowed with a peculiar chemical resistance. It does not react with most chemicals and hence finds use in chemical processing and food equipment industries.

No. One great advantage, though, is that the PTFE bushings are self-lubricating, which means less frequent periods of oiling or greasing for the application.